Tran-Tec 2020

Happy New Year from our team here at Tran-Tec! My father and I purchased Tran-Tec just over 4 years ago and we continue to invest in the company and our team here in Columbus. My father, Robert Dwyer, and I wanted to share with you where we are at and where we expect to be going forward. Our core business remains heatsinks, but we are a full-service machine shop for all your machining needs.

- Chris Dwyer

Expanded Capacity

- 2 MAZAK 4000 II Horizontal Machining Centers installed within last 2 years - 400mm pallets, machine parts on pallet # 1 while operator is loading pallet # 2.

- Installed 2 new vertical mills with expanded capability over 2 retired units – larger work envelopes, higher spindle speeds, faster travels, and Through Spindle Coolant (TSC).

- 2019 Milltronics 5025 w/ TSC, 50 X 25 X 24 travels, 15,000 rpm, Renishaw probing.

- 2017 Haas VF 5 SS w/ 50 X 26 X 25 travels 12,000rpm, Renishaw probing.

Improved Efficiency, Accuracy and Repeatability

- 2019 Haimer tool balancer – improved surface finish and flatness, improved tool engagement leads to better tool life and reduced spindle wear. Balanced tool reduces runout and accuracy of endmills and drills.

- 2018 Omega Tool presetter – reduced tool runout, higher cutting/drilling accuracy, more efficient set-ups.

Expanded Skillsets / Training

- Manufacturing engineer added 2017. Proficient in Solidworks and AutoCAD (10+ years of CAD experience).

- Programming machinist added 2018 w/ 10+ years CAM programming experience. Improved print to finished part delivery time.

- Expanded quality inspection capability (Faro Arm w/ contact and non-contact scanning capability) and additional team members added and trained.

- New machine operator sent through Central Community College Machinist program.

- Four days Mazatrol conversational programming for two machinists at MAZAK Tech Center in Houston, TX.

- Two days training GibbsCAM for our programming machinist at Midwest CAM Solutions in MN to hone Turning/Milling skills for lathe with Milling, Y-Axis, and a second spindle!

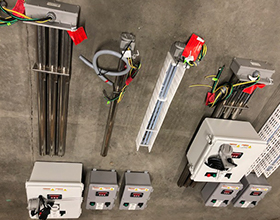

Anodizing Upgrades

- Anodizing chiller upgraded with heat exchanger – improved control of anodizing temperature (68-72F) regardless of load in tanks.

- Boiler retired and replaced with PLC controlled electronic heaters - better control of temperatures in Soap, Etch, Dye and Seal tanks produces more consistent performance in each tank. Heaters for individual tanks helps minimize downtime from boiler failure/repairs.

Coming In 2020

Diversification Of Capabilities - MAZAK Lathe 350U MSY

- Live tooling

- Y-axis

- Dual Spindle (3” through on main)

- 12 tool turret

- One and Done turning/milling Bar Feeder for unattended manufacturing

- Video of smaller machine with similar capabilities

- Estimated Install Feb 2nd 2020